Materials

- Bellows & Liner Materials

- 304/304L S.S. – General Service

- 316/316L S.S. – Greater Resistance to Chemical Attack

- 321 S.S – High Temperature Service

- Monel – High Resistance to Corrosive Environments

- Inconel 600 – Steam Service Where High Trace Chlorides Are Present

- Inconel 625 – High Strength & Temperatures up to 1800F

- Incoloy 825 – High Temperature and Acidic Service

- Nickel 200* – Good Mechanical Properties & High Resistance to Corrosive Environments

Common Applications

Ammonia Injection, Coal Mill, Condensate Pump, Economizer Hopper, Fly Ash, Oxidation Air Pump, Syphon Seal.

*Items are special order materials and not commonly used.

Styles

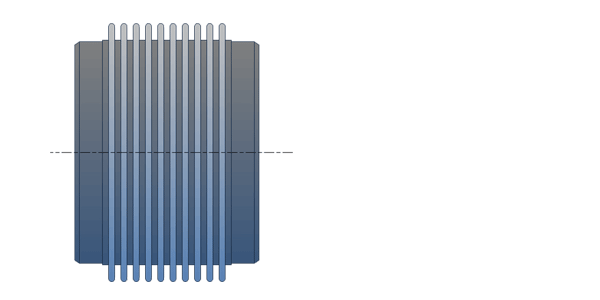

Single Style

- Most common configuration

- Absorbs small amounts of axial, lateral, & angular movements

- Exerts pressure thrust

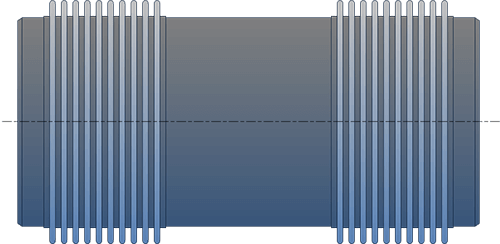

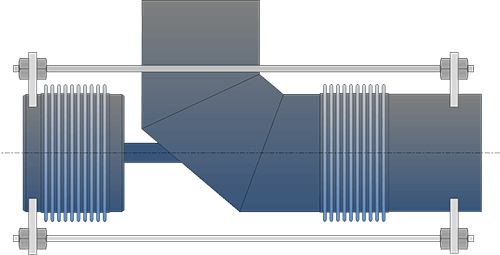

Universal Style

- Absorbs larger lateral movement than single bellows

- Exerts pressure thrust

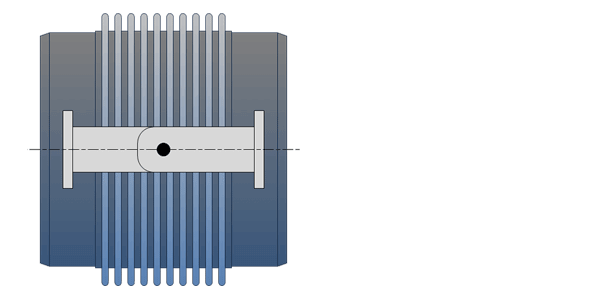

Hinged Style

- Only absorbs angular movement in one plane

- Hinges restrain pressure thrust

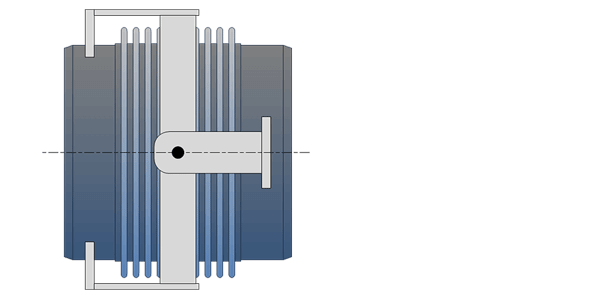

Gimballed Style

- Only absorbs angular movement but in any plane

- Gimbaled mechanism restrains pressure thrust

Pressure Balanced Elbow

- Restrains pressure thrust

- Absorbs small amounts of axial, lateral & angular movements

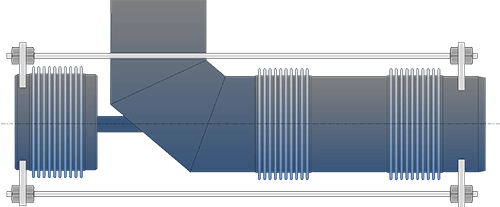

Universal Pressure Balanced Below

- Restrains pressure thrust

- Absorbs large lateral movements

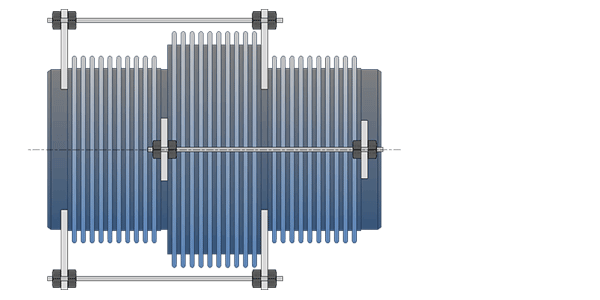

In-Line Pressure Balanced

- Most complicated style

- Restrains pressure thrust

- Absorbs large lateral movements